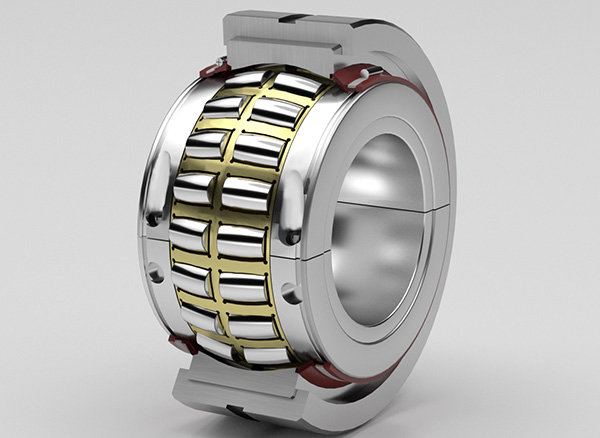

SPLIT BEARING

The design of GSNK split roller bearings makes them suitable for difficult to access applications where installation, removal and maintenance are a challenge, for example, between the head pulley and the gearbox or motor. They are also great for long shafts that need to be supported in multiple locations or on the crankshaft. As a result, split roller bearings can be an ideal solution to reduce machine maintenance and repair downtime. They are usually installed in cartridges that fit different types of housings, forming a complete unit.

GSNK split bearing units can be disassembled into smaller components, simplifying lifting and handling tasks, and can be easily installed or replaced even in the most cramped and inaccessible conditions. The clearance is pre-set, so no field adjustments or specialized assembly tools are required.

Features

Split bearings have low working resistance, stable operation, and the working temperature can reach 180 degrees Celsius. They are very suitable for use in places with low speed, heavy load, large impact force and poor sealing performance. Its biggest advantage is that the bearing can be easily installed and disassembled, which can save a lot of time and reduce production costs.

Application

Split bearings are suitable for all industrial fields, mainly in converter supports, used in various large conveying equipment, cast roller supports, elevators and feeders, paper machinery and other places where it is difficult to remove.

![[Page Title]](/template/default/static/picture/Eng-Bearings_Bnaner_66.jpg)